By Iris Fujiura, Managing Director of Golden Seeds

March 26, 2020

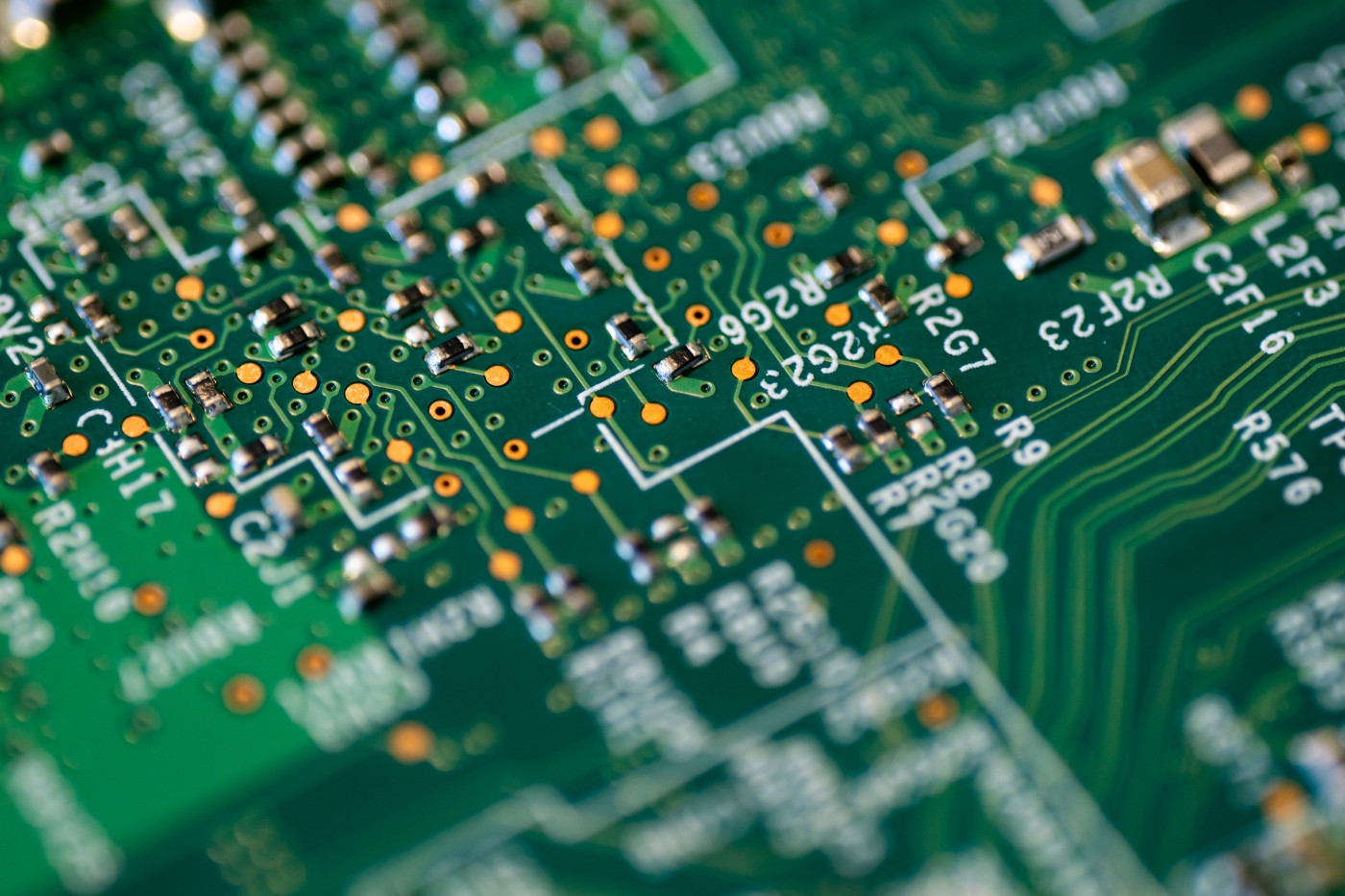

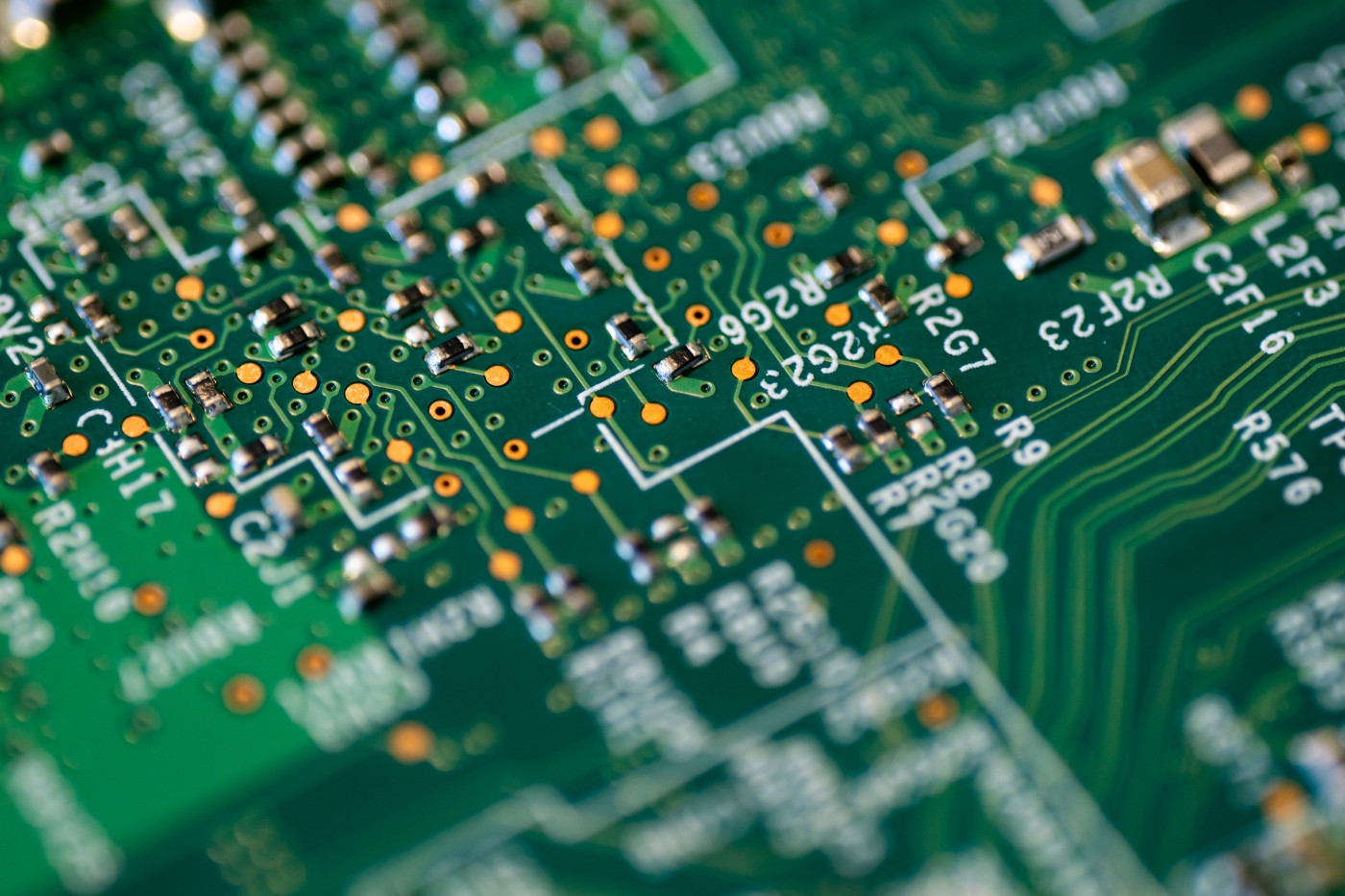

Electronics will never look the same again, thanks to Terecircuits. This startup has developed a process that completely transforms the landscape for electronics manufacturing, resulting in smaller, thinner and lighter devices, with faster and less expensive design cycles. It’s the brainchild of Jayna Sheats, Ph.D. in physical chemistry from Stanford University, and CTO of Terecircuits Corp., who worked in industrial R&D and technical business development for more than 30 years.

Jayna recently spoke with Iris Fujiura, the Golden Seeds deal leader for this investment, about her experiences as a technologist dealing with the financial and business needs of a startup. They also discussed the pivotal role that Golden Seeds has played in jump-starting Terecircuits into the future.

JS: I started this business after I left HP Labs following its merger with Compaq. I wasn’t comfortable with the bureaucracy and where things were going. Though my research there had contributed to some nice technological successes, I wanted to have more of an individual impact. I had ideas about what could be done to foster the Internet of Things — the spread of Internet technology into everyday life. I stumbled around a bit as an entrepreneur and then came up with this technology: a new way to place microelectronic objects to facilitate mass production.

JS: Micro LED displays have many advantages, but one very major disadvantage: placement of the light emitting parts on a backplane. The traditional pick and place machine, which uses a robot arm to move components from one place to another, runs into trouble when objects are very small or there are a large number of them. That’s the situation with micro LED displays. Instead of having an LED as a backlight behind liquid crystals, they require an LED at every pixel — millions of them.

It’s just not practical for a robot arm to handle that.

We developed a new technology that’s a much more efficient way to place these millions of tiny components. I realized a long time ago that you have to be at least 10 times better than the competition or your new technology won’t make it. With micro LED displays, there’s no other solution right now that comes close to ours. We’re much cheaper, faster and more efficient. So this market offers us an ideal entry point, and we think this is where it will be adopted first. But long term, this technology can be used with any kind of chip, on any kind of circuit board or substrate.

JS: There have been tech challenges, of course, but we have clever people working here and they’ve solved these problems pretty quickly. One of the biggest challenges is financing. The investment world has shifted away from hardware and process tech investment and toward software and internet businesses. That’s made it hard to secure money to get to the demonstration stage. Potential investors want to see what they’re funding, so you need to demonstrate your technology — and that takes money.

By collaborating with universities and academic scientists, we’ve minimized the need for expensive infrastructure and gained access to government grants. We were also lucky enough to find a CEO, Wayne Rickard, who excels at fundraising. His presentation skills and personal credibility brought in a lot of our early money.

One caveat I’d offer based on past experience: Be careful about the investors you decide to work with. At a previous company, our investors pulled the plug for reasons many of us considered unwise. So make sure you’re teaming up with the right partners before you take the money.

JS: Finding the right co-founder is critical because you’ll work closely, and the quality of your partnership can make or break your company. In high-tech sectors, you need a business person to complement the technologist. Coming out of a lab research environment, I didn’t know how to find the right person and do human due diligence. Through networking, I found Wayne, who’s been the perfect match.

Company culture should be a priority right from the start because early hires define your culture. The more people you have, the harder it is to change your culture. It’s important to hire people who will foster the kind of environment you want.

JS: We’re close to being able to demonstrate the basic operations of our process in a way that makes it tangible for strategic partners. Though the process is still too primitive for commercialization, we believe it’s enough to convince them to help us develop the technology further. We want to prove the concept and show this repeatability, then have our partners commercialize it using their own engineers and resources. It’s a bit of a challenge to define our company and put boundaries around it: We’ve developed an aid to the manufacturing process, but we’re not a hardware company and we don’t want to be in the business of manufacturing displays.

JS: It has been fantastic and I’ve enjoyed the process. Golden Seeds has the best, most extensive due diligence process of any firm we’ve encountered. They have a deep technical expertise which elicited a strong understanding of the risk and the technology. It also led to thorough but very fair questions. We knew if we could get through that process, we’d have it made. The experience truly shaped our financial strategy, so it’s no wonder Golden Seeds remains our largest investor and a valued resource.